Working on a Film Set Removing a Concrete Water Tank

The Background

The Film Industry in this country and specifically the South East is going from strength to strength with many Film Companies investing in new infrastructure and studios recently. This provides potential work for local companies and opportunities to provide solutions to problems out of their normal working scope.

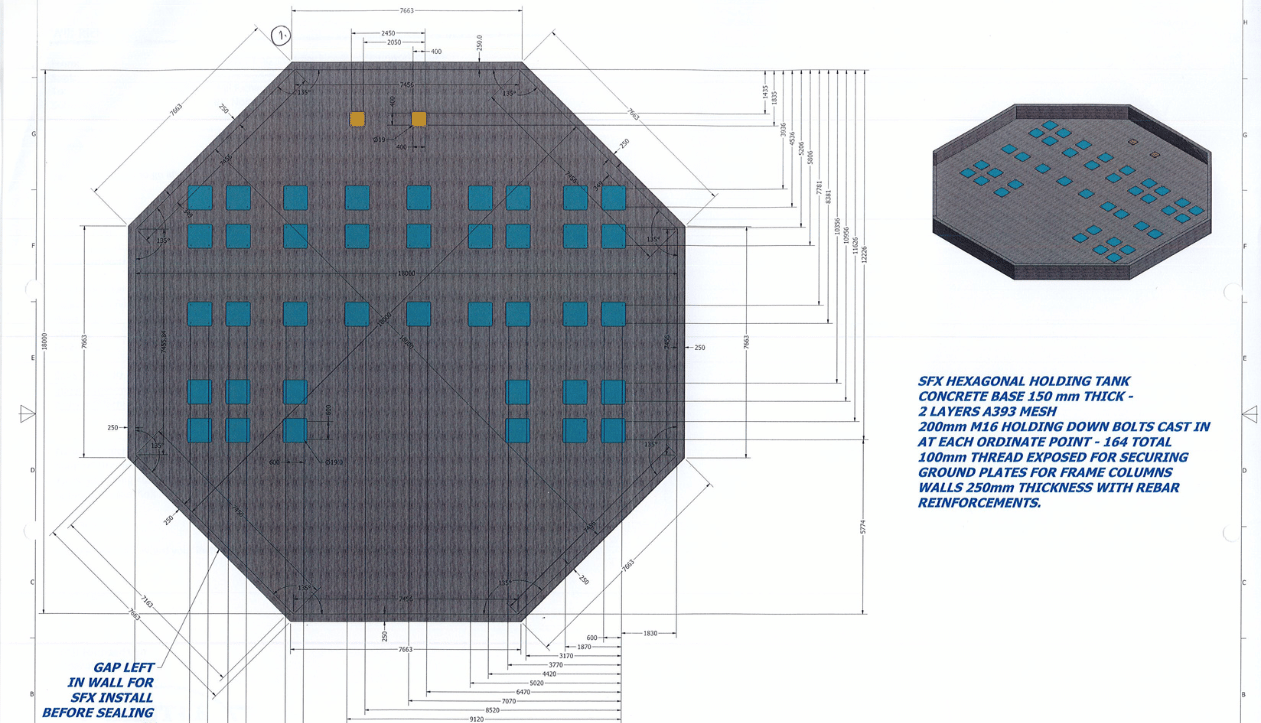

At times, these film productions require the construction of a large tank to replicate water scenes that can then be filmed in a controlled manner. This particular scene required a hexagonal tank, 18.0m x 18.0m with walls 1.0m high, 250mm deep and a concrete floor slab 150mm deep. The tanks purpose was to retain the water for a scene where a large volume of water was released smashing through a glass wall. Traditionally these were constructed using sections of composite material bolted together on site. This had proved costly and was prone to leaking.

Our client, MTD Formwork, provided an alternative cost effective solution which also removed the risk of leaking. They proposed to form the tank using an insitu concrete shell construction method. This would be constructed on top of a protective polystyrene layer to ensure the studio floor wasn’t damaged. The problem they then faced was how to remove this concrete shell once production was completed. This is where the experience and expertise of Castle and Pryor were called upon.

The concrete tank had to be removed within a very tight program to allow the Film Company to hand back the studio on time. It was also essential it did not cause any disruption to other filming activities and day to day operations of the studio complex. Because of this, traditional methods of breaking the concrete with Robotic Demolition machines was not an option due to the noise and vibration disturbing others and damaging the studio floor.

How did we do it?

To work within these restrictions the tank was cut into sections using a Diamond Sawing Technique to allow removal out of the studio and disposal off site.

The walls were removed first using a combination of Tyrolit WSE 1217 and Husqvarna WS 482 track mounted saws to form a cut around the perimeter of the tank at the bottom of the walls flush with the floor. Then, vertical cuts were made at each end of the wall, again, with track mounted saw. The walls were then removed by MTD Formwork using a telehandler to waiting flatbed lorries for disposal off site.

Once the walls were removed the floor was cut into sections using a Husqvarna FS 7000 floor saw. These were then removed using the telehandler for disposal. A Husqvarna K6500 Ring Saw was used to finish any end of cuts that the larger track and floor saws couldn't reach.

MTD Formwork provided water control during the cutting process using wet vac units supplied by Castle and Pryor disposing of the wastewater collected in site skips.

The Results

We had a five day program to remove the tank and working alongside MTD Formwork we completed it within budget, safely in four.

The Film Company were very impressed with what they saw as a titanic task completed at such speed and with minimum disturbance.