Introducing Sindrilla: HAVS Free Drilling Technology is Here

What is HAVS?

Hand Arm Vibration Syndrome (HAVS) - also known as ‘white finger’ - is the severe damage to nerves, blood vessels and joints caused by exposure to vibration. Anyone who uses hand-held power tools for a significant length of time is at risk.

The good news is, HAVS is preventable. The bad news is, there’s no going back once the damage is done - HAVS is permanent. It’s a huge problem in the construction industry and one that, in the past, hasn’t been taken too seriously. But it has always been at the forefront of our minds and that‘s why we diamond drill.

Now, times are changing. In 2018 alone, we’ve seen leading names in construction dealt hefty fines for failing to take the right precautions to protect their teams against HAVS. We have to find a different way of doing things.

What is rotary percussion drilling?

Rotary percussion (RP) drilling combines a rotating and percussive or ‘hammering’ action in the same drill. This method is widely used across the construction industry because it’s a cheap and effective way to anchor steel frames into the ground, to drill rough sided holes into concrete, or when you need to connect one concrete slab to another using reinforced steel dowels.

So, what’s the problem with rotary percussion drilling?

The biggest drawback to rotary percussion drilling is the vibration caused by the hammer action. Hand and Arm Vibration Syndrome (HAVS) is caused by excessive exposure to vibration. When it comes to reasons why construction workers develop HAVS, rotary percussion drilling is one of the biggest culprits.

Whether you’re a construction worker or a DIY enthusiast, using a RP drill is often the quickest and most cost effective way to get the job done. Unlike diamond drilling, it doesn’t require much training but the operator will be exposed to vibration.

Everyone can do it. That’s why people will still rotary percussion drill for several hours, day in, day out, and think nothing of it. But that’s all changing, thanks to better health and safety regulations and increasing awareness - and we’re changing with it.

When does vibration exposure become a HAVS risk?

Guidance from the Health and Safety Executive (HSE) specifies the exposure levels at which employers need to take action, to protect their team against HAVS. There are two basic action levels when it comes to HAVS. We only work up to the first action level (see EAV below) as recommended by the HSE. Working between the first and second action levels is for occasional use.

- Exposure Action Value (EAV). This is the amount of daily vibration exposure above which employers need to take action to control exposure. The greater the exposure level, the greater the risk of workers developing HAVS. For hand-arm vibration the EAV is a daily exposure of 2.5 m/s2 A(8).

- Exposure Limit Value (ELV). This is the maximum amount of vibration exposure that one person can legally be exposed to in a day and it must not be exceeded. For hand-arm vibration the ELV is a daily exposure of 5 m/s2 A(8)

If any of your employees will regularly be exposed to vibration levels above the EAV, then you must provide health surveillance. Even regularly reaching the EAV will increase your chance of developing ‘white finger’. This process begins with a questionnaire but can involve referring employees to an occupational therapist if exposure or symptoms escalate.

Measuring HAV exposure

The risk of exposure is calculated using ‘exposure points’ which should not exceed 100 points if you want to stay under the EAV. For example, a person can operate a Hilti TE-80 ATV drill for up to 53 minutes per day before action is required, if it’s being hand-held.

Beyond 100, points you will be required to take action by providing health surveillance and have employees checked out by a health professional which becomes costly and isn’t practical for most. The legal limit value (ELV) is 400 points per person, per day.

Industries at high-risk for HAVS

If you work in an industry where the level of vibration exposure is regularly above the EAV then you need to take action.

- Construction

- Engineering

- Forestry

- Foundries

- Vehicle manufacture and repair

- Maintenance of parks, gardens, grounds etc

- Shipbuilding and ship repair

- Utilities like gas, water and telecommunications

For more information on which tools pose a high risk, please refer to page 3 of this guide from the HSE.

What does this mean for employers?

As an employer, you are responsible for controlling the HAVS risk in your workplace. People who operate hammer action drills for more than one hour a day are considered high risk for developing HAVS. Those who operate hammer action tools for 15 minutes a day are still considered medium risk. You can use the HSE’s free Hand Arm Vibration exposure calculator to work out an individual employee’s total exposure. There is also guidance available on how to use the HAV exposure calculator.

Find out more about your legal obligations as an employer on the HSE website.

Introducing Sindrilla: Hands-free percussion drilling

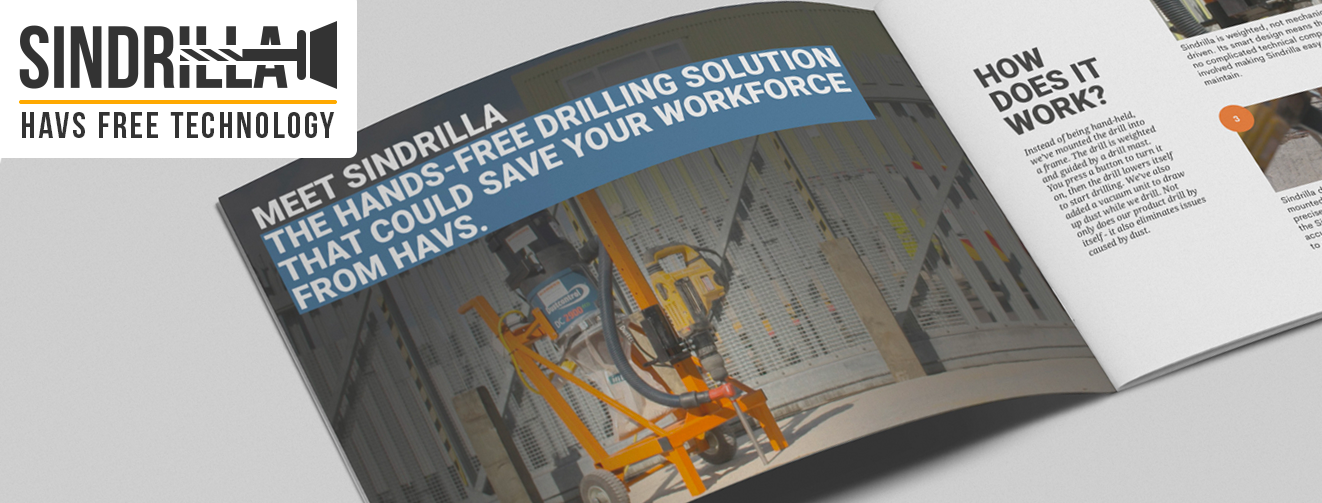

Meet Sindrilla. The hands-free drilling solution that could save your workforce from HAVS.

How does it work?

Instead of being hand-held, we’ve mounted the drill into a frame. The drill is weighted and guided by a drill mast. You press a button to turn it on, then the drill lowers itself to start drilling. We’ve also added a vacuum unit to draw up dust while we drill. Not only does Sindrilla drill by itself - it also eliminates issues caused by dust.

- Sindrilla is weighted, not mechanically driven. Its smart design means there are no complicated technical components involved making Sindrilla easy to maintain.

- Sindrilla uses standard stuff. Everything is 110 volt.

- Sindrilla is ready to go. No special training is required, so you can use Sindrilla on-site straight away.

- Sindrilla is safer. No more spraining your wrist when the drill gets jammed. If there’s a jam, Sindrilla will stop automatically.

- Sindrilla drills more accurately. Rig mounted drilling is actually a lot more precise than hand-held drilling. Why? Because when you’re hand drilling, you might not be holding the drill vertically or horizontally, so it’s easy not to be aligned. Once the Sindrilla rig is set, every hole will be accurately aligned - whether you choose to drill straight or angled holes.

The economic impact of Sindrilla and HAVS

Currently, if you employ a contractor to carry out work using rotary percussion drilling, you’ll essentially be paying for a full day’s labour for around 53 minutes worth of work per day (depending on your drill of choice). Even if you do have 8 people working on a site who are willing and skilled enough to take 53 mins a day each on the drill, this would be very difficult to manage. With our hands-free drilling solution, the same person can drill all day long with no adverse effects.

We could be saving your company thousands in lost labour costs, every day.

Putting Sindrilla to the test at Heathrow Airport

We currently have a drill on trial with Morgan Sindall, at London Heathrow Airport. Morgan Sindall’s team are using the drill to pin shuttering to existing concrete. Here’s what Andrew Swann, Morgan Sindall’s Aviation Project Manager had to say about Sindrilla:

Sindrilla in Action

Of course, we’ve also tested Sindrilla ourselves. Last year, the Castle & Pryor team were contracted to add a new storey to the long stay car park at Gatwick Airport. The job required about 1200 holes to be percussion drilled to fix steel to the concrete bases.

These holes were in groups of four, so we adapted our original Sindrilla design to accommodate four drills in one frame. We nicknamed it, Quadrilla. We had 300 bases to drill but all the guys had to do was move the frame along, each time. There really is no limit to the possibilities, we could mount any number of drills to the rig. You could have 10 drills going at a time, if you wanted to.

Watch Sindrilla in action

The burning question: why haven’t we done this before?

We have people in the Castle & Pryor team who’ve been with us for 20, even 30 years. Since we started working on Sindrilla they’ve all been saying,

“This is the best thing I’ve ever seen!” and “Why didn’t anyone think of this before?”

And it’s a good question.

But until now, there has been no real hands free solution to nerve damage and HAVS when using conventional rotary percussive drills within the construction industry. We’ve been working around the HSE HAVS guidelines by rotating labour and using dampened tools which has only alleviated the problem - until now.

Could Sindrilla protect your company from HAVS? Call us today on 01252 524 080 to note your interest. Or get in touch with your questions and our team will be happy to help.

GET Sindrilla. BEAT HAVS.